Understanding Your Car's Braking System: A Comprehensive Guide

Your vehicle's braking system is arguably its most critical safety feature. While advancements in automotive technology have introduced sophisticated systems like autonomous emergency braking and collision avoidance, the fundamental braking system remains your primary means of controlling and stopping your vehicle in everyday driving and emergency situations.

Despite its importance, many drivers have only a vague understanding of how their braking system works and the warning signs that indicate potential problems. This comprehensive guide explores the components and operation of modern braking systems, how to recognize brake issues, and the importance of regular maintenance.

The Fundamentals: How Braking Systems Work

At its core, your vehicle's braking system converts kinetic energy (motion) into thermal energy (heat) through friction. When you press the brake pedal, you initiate a chain reaction that ultimately creates friction at the wheels, slowing or stopping your vehicle.

Hydraulic Principles

Most vehicles use a hydraulic braking system that multiplies the force applied to the brake pedal. When you press the pedal:

- The brake pedal pushes a piston in the master cylinder

- The master cylinder pressurizes brake fluid in the brake lines

- This hydraulic pressure is transmitted equally to all four wheels

- At each wheel, the pressure activates either a caliper (disc brakes) or wheel cylinder (drum brakes)

- These components create friction against rotating parts connected to the wheels

This hydraulic system provides several advantages:

- Force multiplication, allowing relatively light pedal pressure to create substantial braking force

- Equal pressure distribution to all wheels (though many vehicles intentionally apply more force to front brakes)

- Split circuits that provide some braking capability even if one circuit fails

Key Components of Modern Braking Systems

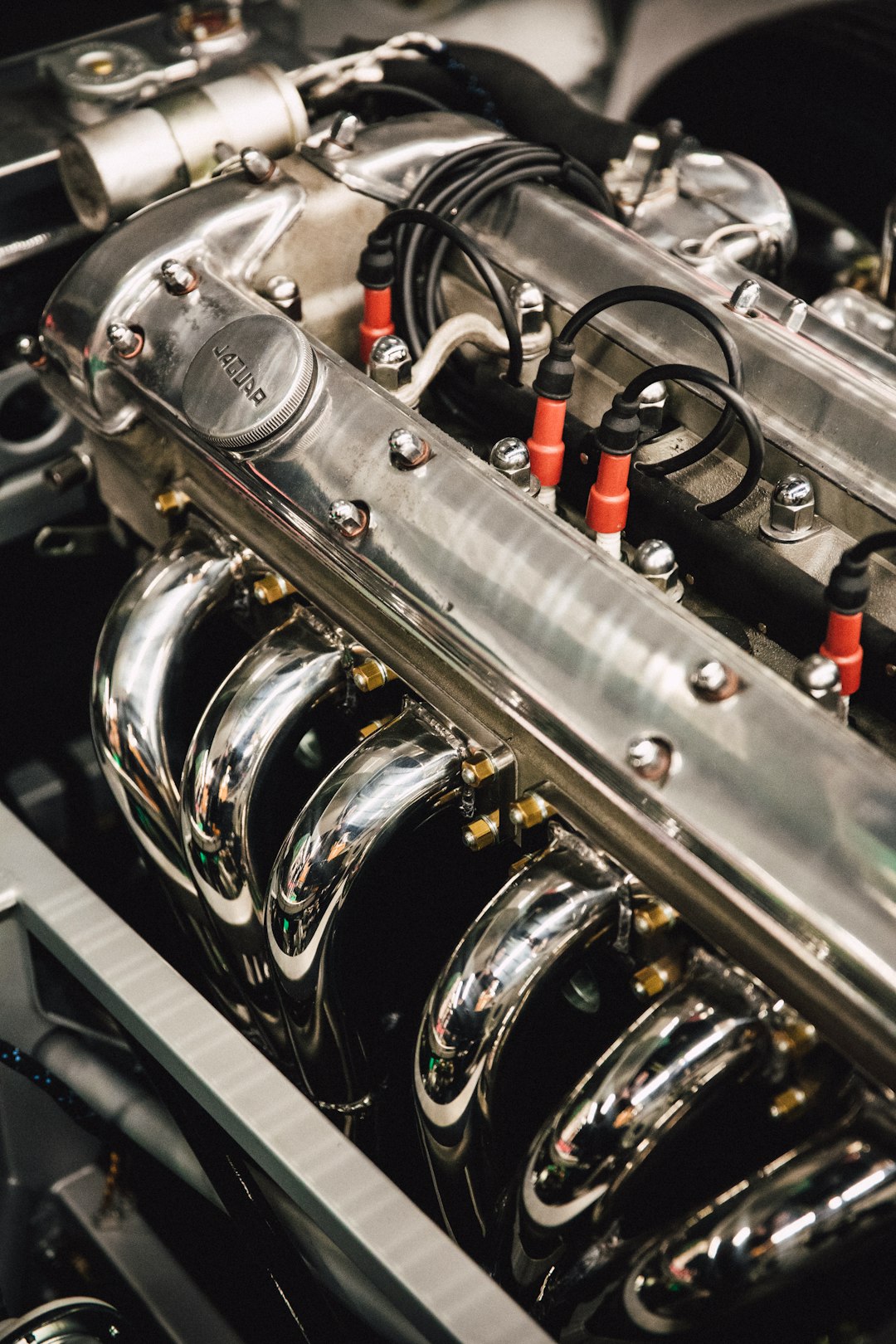

1. Master Cylinder

The master cylinder is the heart of the hydraulic braking system. When you press the brake pedal, it directly activates the master cylinder's pistons, which pressurize the brake fluid. Modern master cylinders typically have dual circuits, meaning they can operate two separate hydraulic systems simultaneously—usually one for the front wheels and one for the rear. This redundancy ensures that if one circuit fails, the other can still provide some braking capability.

2. Brake Fluid

Brake fluid is the hydraulic medium that transmits pressure throughout the system. It has several critical properties:

- High boiling point: Typically over 230°C (446°F) for DOT 4 fluid

- Incompressibility: Allows for direct and immediate transfer of pressure

- Corrosion inhibitors: Protects metal components in the system

Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This water contamination lowers the fluid's boiling point and can lead to brake fade under heavy use. For this reason, brake fluid should be replaced periodically (typically every 2 years) regardless of mileage.

3. Brake Lines and Hoses

The pressurized brake fluid travels from the master cylinder to each wheel through a network of brake lines (rigid metal tubes) and brake hoses (flexible sections near the wheels to accommodate suspension movement). These components must withstand high pressure while resisting corrosion and physical damage.

4. Disc Brakes

Most modern vehicles use disc brakes at the front wheels, and many use them at all four wheels. A disc brake system consists of:

- Rotor (disc): A flat, round piece of metal attached to and rotating with the wheel

- Caliper: A clamp-like device that straddles the rotor

- Brake pads: High-friction material that presses against the rotor when the brakes are applied

- Pistons: Cylindrical components inside the caliper that push the brake pads against the rotor when hydraulic pressure is applied

When you apply the brakes, hydraulic pressure forces the pistons outward, pressing the brake pads against both sides of the rotor. This creates friction that converts the kinetic energy of the spinning wheel into heat, slowing the vehicle.

5. Drum Brakes

While less common on newer vehicles, drum brakes are still found on the rear wheels of many cars, particularly in the budget segment. A drum brake system includes:

- Drum: A bowl-shaped component attached to and rotating with the wheel

- Wheel cylinder: Converts hydraulic pressure into mechanical force

- Brake shoes: Curved friction material that presses against the inside of the drum

- Return springs: Pull the brake shoes away from the drum when pressure is released

- Self-adjusters: Maintain proper clearance between shoes and drum as friction material wears

When the brakes are applied, hydraulic pressure extends the wheel cylinder's pistons, forcing the brake shoes outward against the inner surface of the drum. This creates friction that slows the wheel.

6. Parking Brake System

Also known as the emergency brake or handbrake, this system operates mechanically rather than hydraulically. When engaged, it typically activates the rear brakes through a cable system. Modern vehicles may use an electronic parking brake that employs small electric motors to apply the rear brakes.

Advanced Braking Technologies

Anti-lock Braking System (ABS)

ABS prevents wheel lockup during hard braking, helping you maintain steering control in emergency situations. The system includes:

- Wheel speed sensors: Monitor the rotation speed of each wheel

- Hydraulic control unit: Contains solenoid valves that can modulate brake pressure

- Electronic control unit: Analyzes sensor data and controls the hydraulic unit

- Return pump: Restores pressure during ABS activation

When the system detects that a wheel is about to lock up (indicated by a sudden deceleration of that wheel relative to the others), it momentarily reduces hydraulic pressure to that wheel. This allows the wheel to regain traction before reapplying the brake. This process can occur up to 15 times per second, creating the pulsing sensation in the brake pedal during ABS activation.

Electronic Brake-force Distribution (EBD)

EBD works with ABS to automatically vary the amount of force applied to each wheel's brake based on road conditions, speed, and loading. This ensures optimal braking performance and stability. For example, during a stop, weight transfers to the front of the vehicle, increasing the traction of the front tires. EBD automatically applies more braking force to the front wheels to take advantage of this increased traction.

Brake Assist

Studies have shown that many drivers don't apply sufficient force to the brake pedal during emergency situations. Brake Assist systems detect panic braking (based on the speed and force with which the pedal is pressed) and automatically apply maximum braking power, potentially reducing stopping distances in emergencies.

Electronic Stability Control (ESC)

While not strictly a braking technology, ESC works in conjunction with the braking system to help maintain vehicle control during cornering, especially in emergency maneuvers. ESC can apply individual brakes to help correct understeer or oversteer situations.

Common Brake Problems and Warning Signs

Recognizing the warning signs of brake problems is crucial for safety. Here are common issues and their symptoms:

Worn Brake Pads/Shoes

Warning signs:

- Squealing or screeching noise when brakes are applied

- Grinding metallic noise (indicates pads are completely worn)

- Brake warning light on dashboard (some vehicles have pad wear sensors)

- Reduced braking effectiveness

- Vehicle pulling to one side during braking

Brake pads typically last between 30,000-70,000 kilometers, depending on driving habits, vehicle weight, and pad quality. City driving with frequent stops will wear pads faster than highway driving.

Warped Brake Rotors

Warning signs:

- Pulsating brake pedal during braking

- Steering wheel vibration during braking

- Intermittent squeaking noise

Rotors can warp due to excessive heat from hard braking or from uneven cooling after periods of heavy use. This is particularly common after descending steep mountain roads while braking frequently.

Brake Fluid Issues

Warning signs:

- Soft or spongy brake pedal

- Brake pedal slowly sinks to the floor when held down

- Brake fluid warning light on dashboard

- Visibly low fluid level in the reservoir

- Fluid appears dark brown or black (should be clear to amber)

These symptoms could indicate a leak in the system, air in the brake lines, or severely degraded fluid. Any of these conditions requires immediate attention.

Caliper Problems

Warning signs:

- Vehicle pulls to one side during braking

- Uneven brake pad wear

- One wheel significantly hotter than others after driving

- Brake drag (vehicle seems to fight against acceleration)

Calipers can seize due to corrosion or debris, causing them to either not apply properly or not release fully after braking.

ABS System Issues

Warning signs:

- ABS warning light illuminated on dashboard

- Regular braking functions but no ABS pulsation during emergency stops

- ABS activating under normal braking conditions

Modern ABS systems have self-diagnostic capabilities and will illuminate a warning light if a fault is detected. While the standard braking system typically continues to function, the anti-lock capability may be compromised.

Brake Maintenance: Best Practices for Australian Conditions

Australia's diverse environment—from dusty Outback roads to tropical humidity and alpine conditions—presents unique challenges for brake maintenance. Here are best practices for keeping your braking system in optimal condition:

Regular Inspection

- Have brakes inspected at every service interval (typically 10,000-15,000 km)

- Visual checks can be performed through wheel spokes (look for thin pads or grooved rotors)

- Pay attention to unusual noises or sensations when braking

Brake Fluid Maintenance

- Check fluid level monthly (should be between MIN and MAX marks on reservoir)

- Replace fluid every 2 years regardless of mileage

- Use the correct fluid type as specified in your owner's manual (usually DOT 3 or DOT 4)

- In humid tropical regions like Far North Queensland, consider more frequent fluid changes

Important: Brake fluid is highly corrosive to paint and toxic. Handle with care and dispose of old fluid properly at recycling centers.

Regional Considerations

Different Australian regions present specific challenges for braking systems:

- Coastal Areas: Salt air can accelerate corrosion of brake components. Regular underbody cleaning is recommended.

- Outback/Dusty Regions: Fine dust can contaminate brake fluid and wear seals. More frequent inspection of dust boots and seals is advisable.

- Alpine Regions: Frequent mountain driving causes increased heat and wear. Consider upgrading to high-performance brake pads if you regularly drive in mountainous areas.

- Tropical Regions: High humidity accelerates fluid deterioration. More frequent brake fluid changes may be necessary.

Driving Habits That Extend Brake Life

How you drive significantly impacts brake component lifespan:

- Anticipate stops: Look ahead and coast to reduce speed before applying brakes

- Avoid riding the brakes: Particularly on downhill sections (use engine braking by shifting to a lower gear)

- Practice smooth braking: Gradual application puts less stress on components than hard, sudden stops

- Reduce unnecessary weight: Remove unneeded heavy items from your vehicle

When to Replace Brake Components

Brake Pads

Replace when:

- Friction material is 3mm or less in thickness

- Uneven or abnormal wear is present

- Excessive noise occurs during braking

Tip: Always replace brake pads in axle pairs (both front wheels or both rear wheels) even if only one side shows significant wear.

Rotors

Replace or machine when:

- Visible scoring or grooves are present

- Thickness is at or below the minimum specification (stamped on the rotor)

- Warping causes pulsation during braking

- Blue discoloration indicates overheating

Note: Many modern vehicles use thinner rotors that cannot be machined and must be replaced when worn.

Brake Fluid

Replace when:

- Fluid appears dark or contains visible particles

- Every two years regardless of appearance (due to moisture absorption)

- After major brake system repairs

Other Components

- Brake hoses: Replace if cracked, bulging, or leaking (typically every 5-7 years)

- Calipers: Replace if pistons are seized, boots are damaged, or slide pins don't move freely

- Wheel cylinders: Replace if leaking or if pistons don't move freely

DIY vs. Professional Brake Service

While some brake maintenance tasks can be performed by knowledgeable DIYers, others are best left to professionals:

Suitable for DIY (with proper tools and knowledge)

- Visual inspection of brake components

- Checking brake fluid level

- Replacing brake pads on most vehicles

- Cleaning and lubricating caliper slide pins

Professional Service Recommended

- Brake fluid flushing and replacement

- Rotor replacement or machining

- Caliper rebuilding or replacement

- Drum brake service

- ABS system diagnosis and repair

- Any hydraulic system repairs

Safety Warning

Brake system repairs directly affect vehicle safety. If you're uncertain about your ability to properly complete a brake repair, always consult a professional. Improperly installed brake components can lead to brake failure and serious accidents.

Conclusion

Your vehicle's braking system is a sophisticated and vital safety system that deserves regular attention and maintenance. Understanding how it works and recognizing the warning signs of potential problems can help you make informed decisions about maintenance and repairs.

At ViciNitia, we recommend having your braking system professionally inspected at each service interval and addressing any issues promptly. Our technicians are trained to diagnose and repair all types of brake systems, from basic maintenance to complex ABS troubleshooting.

Remember, proper brake maintenance isn't just about avoiding repair costs—it's about ensuring your vehicle can stop safely and predictably when you need it most. Don't compromise on brake maintenance or quality replacement parts, as they play a crucial role in protecting you and your passengers on Australian roads.

If you're experiencing any of the warning signs mentioned in this article or if it's been more than two years since your last brake fluid change, contact ViciNitia to schedule a comprehensive brake system inspection. Your safety is worth it.

Comments (14)

Alan Brown

April 6, 2023 at 8:45 AMThis is one of the most comprehensive explanations of braking systems I've read. I finally understand why my brake pedal sometimes pulsates during hard stops. It's the ABS doing its job, not something broken! Thanks for the clear explanation.

Sarah Thompson

April 7, 2023 at 11:23 AMMy mechanic just told me I need new rotors with my brake pads, which is going to cost twice as much. Is this really necessary or are they just trying to upsell me?

James Parker

April 7, 2023 at 2:47 PMHi Sarah, great question! It's common practice to replace or resurface rotors when changing pads, and there are good reasons for this. When rotors and pads wear together, they create matching wear patterns. Putting new pads on worn rotors can cause uneven contact, leading to noise, vibration, and reduced braking effectiveness. Additionally, if the rotors are below minimum thickness or have significant grooves or heat damage, replacement is necessary for safety. I'd suggest asking your mechanic to show you the condition of your rotors so you can see why they're recommending replacement.

Michael Chen

April 8, 2023 at 9:52 AMI regularly drive in the Snowy Mountains during winter. Are there any special considerations for brake maintenance in these conditions?

Leave a Comment